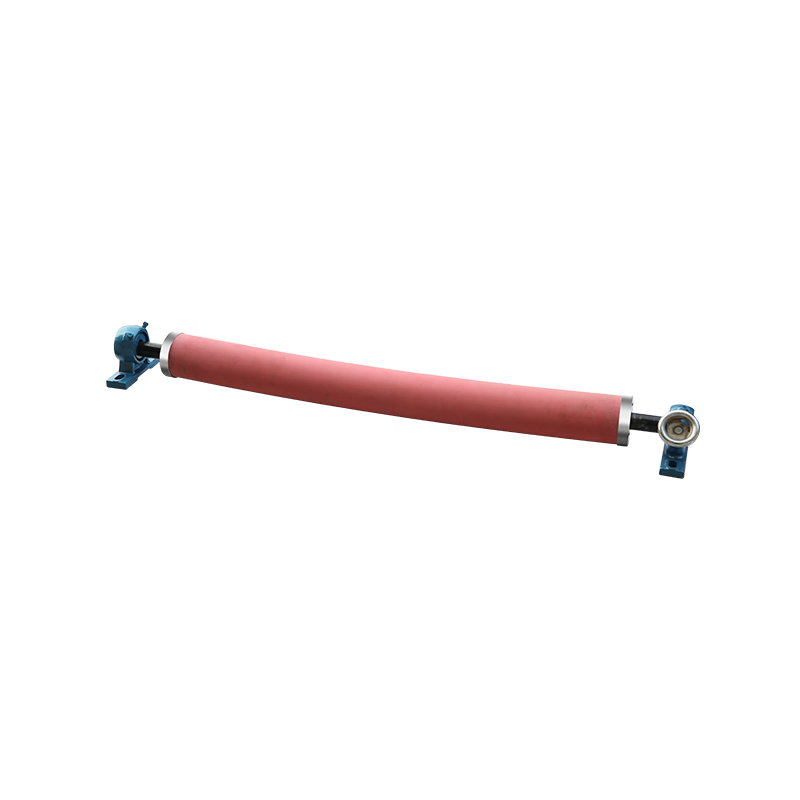

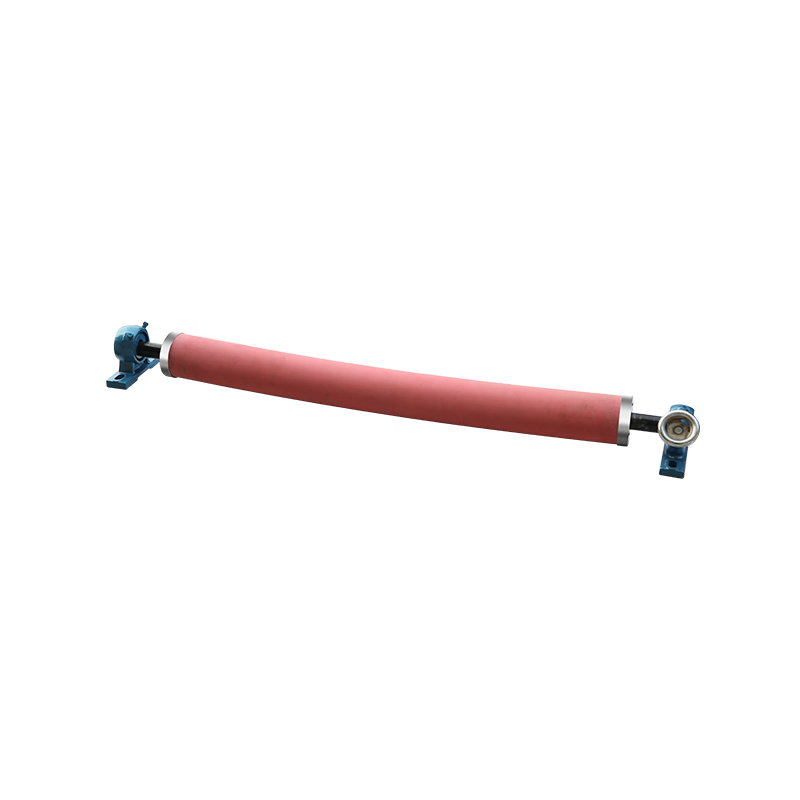

The selection of materials plays a key role in the design and functionality of banana rollers. These components must withstand the rigors of industrial environments, where they are exposed to continuous use, varying temperatures, and potentially corrosive substances.

In industries such as textiles and paper manufacturing, banana rollers often come into contact with chemical treatments, dyes, or water. For this reason, material selection is critical. Rubber, for example, offers flexibility and wear resistance, making it an ideal choice for banana rollers used in more sensitive applications. On the other hand, metals like stainless steel are often favored in heavy-duty applications because of their strength and ability to endure more abrasive conditions.

The surface texture of banana rollers is also a consideration in material Banana Roller Design. A smooth finish can prevent abrasion, while a textured surface may be beneficial for improving grip and preventing slipping during material handling.

Ultimately, the choice of material affects not only the roller’s performance but also its lifespan and the level of maintenance required. An optimal material selection can contribute to more efficient operations and reduced downtime in industrial settings.

https://www.cbbmachine.com/product/banana-roller/customizable-banana-roller.html

| Number |

L1 |

L2 |

L3 |

Applicable base material width |

| 1 |

590 |

678 |

730 |

500mm |

| 2 |

725 |

830 |

880 |

600mm |

| 3 |

1175 |

1265 |

1315 |

1100mm |

| 4 |

1220 |

1278 |

1330 |

1100mm |

| 5 |

1500 |

1560 |

1610 |

1320mm |

| 6 |

1435 |

1488 |

1540 |

1320mm |

| 7 |

1760 |

1810 |

1870 |

1600mm |

| 8 |

1805 |

1828 |

1880 |

1600mm |

Share this page with your family and friends.