Newsletter

Thank you for subscribing.

You have already subscribed.

Posted by - coatingline geartech -

on - Feb 17 -

Filed in - Business -

265 Views - 0 Comments - 0 Likes - 0 Reviews

Recent advancements in technology have greatly improved the efficiency and capabilities of ACP Production Line. Automation and digitalization are now key components of modern production systems, allowing manufacturers to achieve more consistent and precise results.

Automation systems can control the entire production process, from the feeding of raw materials to the cutting and packaging of the finished panels. Sensors and cameras monitor key parameters, such as temperature and pressure, ensuring optimal conditions throughout production. This reduces the need for manual intervention and minimizes the chances of human error.

Additionally, the integration of data analysis tools into the production line has enabled real-time monitoring and predictive maintenance. By analyzing production data, manufacturers can identify inefficiencies and address potential issues before they lead to downtime, further improving the line's overall productivity.

Another innovation is the development of more energy-efficient machines. These machines consume less power while maintaining high output, contributing to cost savings and reducing the environmental footprint of the production process.

As these technological advancements continue to evolve, the ACP production line becomes more capable of meeting the increasing demand for high-quality panels in industries such as construction, transportation, and signage.

https://www.coating-line.com/product/aluminum-composite-panel.html

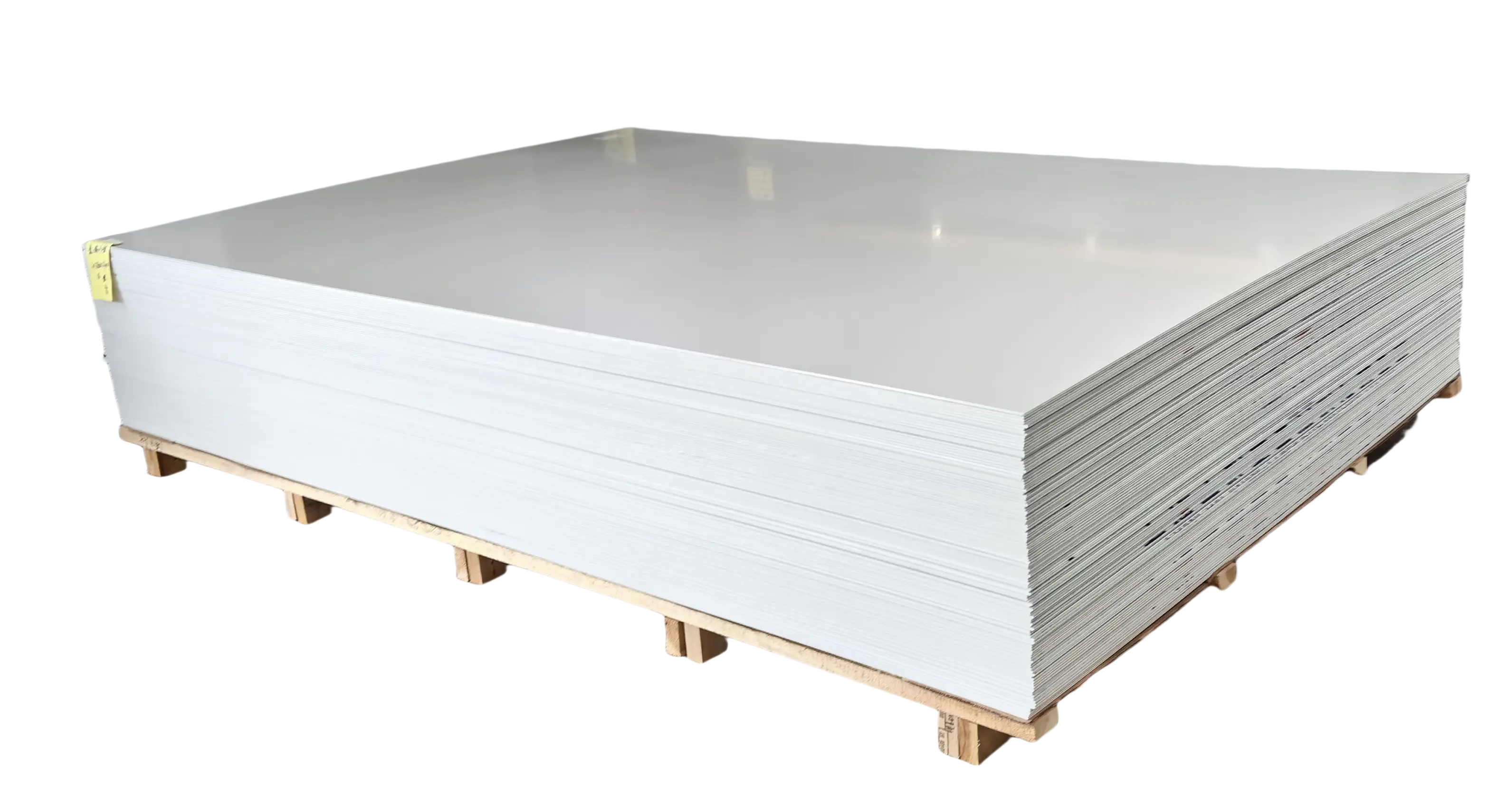

In today's construction industry, Aluminum Composite Panel (ACP) has emerged as a versatile and popular material due to its lightweight nature, durability, and aesthetic appeal.

Our Mission... “To assist disaster survivors by providing a source for them to come together in time of need, to aid in the listing of events, information and other forms of assistance, and continuing support through the recovery process.”

Share this page with your family and friends.